Complete post-trip inspection checklist for CDL drivers

By The Schneider Guy

Estimated reading time: 5 minutes

Performing a post-trip inspection is one of the most important daily tasks a professional truck driver does. Post-trips allow drivers to ensure their tractor and trailer are in good, safe condition after completing a trip.

Keep reading to learn more about post-trip inspections and see what needs to be on your post-trip inspection checklist.

What is a post-trip inspection?

A post-trip inspection is a mandatory inspection performed after driving to ensure nothing went wrong with the equipment while operating it. These inspections must be performed on every piece of equipment a driver operates throughout the day.

A thorough inspection could take anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4).

Post-trip inspection requirements

A driver is required to complete a post-trip inspection:

- Whenever a trailer is dropped.

- At the end of each day.

Post-trip inspections are required by Federal Motor Carrier Safety Association (FMCSA) regulation 396.11. If any faults or defects are found during the inspection, drivers are required to submit a Driver Vehicle Inspection Report (DVIR).

Complete post-trip inspection checklist

1. Passenger-side engine:

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbo charger: No oil or exhaust leaks.

- Engine air duct work: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Mounting secure.

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Inner oil seal (not visible): Check for leaks (look for oil running down brake drum or tire).

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight.

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 5/32 mins, 4/32 DOT.

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks, no missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secured mounting, no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Engine air duct work: No cuts, clamps secured.

- Brake master cylinder: Correct fluid level, no leaks.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 3/32 min, 2/32 DOT.

- Air bag (bellows): Fully inflated, secure mounting, not ruptured.

- Shock absorber: Secure mounting, not leaking oil.

7. Side of cab:

- Mirrors: Mounting secure, no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Mounting secured, cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures cap to the tank secure.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

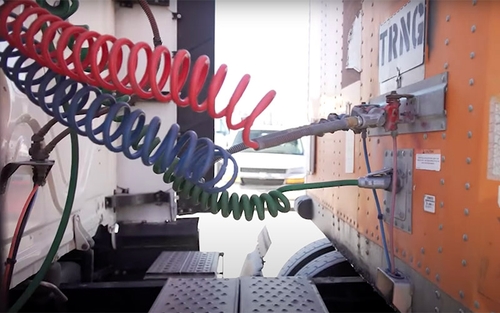

- Electrical cord: No bare wire, no corrosion, check plug at end of cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab air bag (bellows): Not ruptured, securely mounted.

9. Drive shaft/rear frame:

- Drive shaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds, no missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line/glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Placard holder: Not broken, all rivets intact.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Placard holders: Not broken, no missing rivets.

- Reflector tape: Clean.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 3/32, air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Mounting secure, band clamp secure.

15. Gauges/inside the truck:

- Tachometer: 1000-1500.

- Water temp: 180-205 degrees.

- Fuel: Matches visual when looking in tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."